Benjamin Stoddard

Member-

Posts

10 -

Joined

-

Last visited

-

Ben Stoddard, 3D Printed ROTK Build Thread

Benjamin Stoddard replied to Benjamin Stoddard's topic in Rogue One Build Threads

And now we have the chest glued together. This took a while because I wanted to let each piece sit for at least 24 hours to fully cure. The Gaps in the armor are from slight misalignment. Some of the edges I had over done with the mouse sander. As previously stated, gaps are covered with Bondo. There seems to be very little that I cannot fix with Bondo and sanding thus far. Bondo to the rescue!Dont forget the edges, they will be visible! I used 400 grit sandpaper by hand. Finished the 1st round of Bondo, and I sprayed a layer of white paint so I can see just how visible these gaps are. After drying, more Bondo will be added to any remaining gaps in the part. -

Ben Stoddard, 3D Printed ROTK Build Thread

Benjamin Stoddard replied to Benjamin Stoddard's topic in Rogue One Build Threads

I have sanded all of the Chest Pieces individually, which was very helpful in keeping everything manageable. I could focus on one smaller part and really give it the attention in needs instead of worrying about an entire torso sized piece. 80 Grit sandpaper was used directly on the print, and then coated with Rust-oleum filler primer. After drying, I added the Bondo in parts which had very visible layer lines and sanded it with 150 Grit Sandpaper. The next thing to do was another layer of sandable filler primer, and Bondo in areas that still had visible layer lines. I did the same process of filler primer, and Bondo, had it dry, then did the parts with 220 Grit sand paper. Once I finished the whole chest with just the mouse sander, it was time to get into the tighter spaced parts. I waited to the end to do this just because I thought it might be a bit faster. I didn't notice any difference in quality by doing the tight parts last in this case. I went from 150 to 220 Grit. and then washed off the parts post sanding and sprayed with one last layer of filler primer. Last layer of filler primer before wet sanding with 400 grit. Parts were then wet sanded with a 400 Grit Sandpaper by hand. I do this by hand so that I can ensure I don't hold the sander in one spot for too long and ruin all my progress with sanding it this smooth. I filled up a 5-gallon bucket with some warm water and dipper the pieces in the get them wet in a controlled environment. And now I am at the point where I get to painstakingly glue all 8 of these pieces together... I picked up some Dewalt clamps with rubber tips so that I don't scratch the parts while the glue dries. As you can see, there will be some seams from assembly. You need to ensure that you send the edges that will connect together, especially if you do not use any sort of alignment on your print. What I mean is that you have put rods and cuts into the sections to help you align them perfectly. I did not do this because of my inexperience with blender, but i will be attempting to do so with further prints. The seams will be simply filled in with bondo, and sanded down to the same grit as the rest of the chest once assembled. -

Ben Stoddard, 3D Printed ROTK Build Thread

Benjamin Stoddard replied to Benjamin Stoddard's topic in Rogue One Build Threads

Revlimiter Thanks for the heads up, I plan to either line the inside with fiberglass or I will cast the armor to make a mold somehow. I will most likely line it with fiberglass though. -

Ben Stoddard, 3D Printed ROTK Build Thread

Benjamin Stoddard replied to Benjamin Stoddard's topic in Rogue One Build Threads

Sly11 That is an excellent question, and I wish that I had a detailed log on this to give the most accurate answer. I went through my slicer program to calculate the build times. The data below is for the entirety of the Left and Right Arm, Buttplate, Cod Piece, Chest Plate, Backplate, Helmet, Front and Back Belt, and Thermal Detonator. If Everything was printed only one single time, no errors, the filament did not crack as I removed supports to a level where glue and sanding could not fix, I would have had my printer running for: 46 Days, 9 Hours, 42 Minutes. (I do not have an exact number for filament at this time) Again, keep in mind that I do have failures, and I have to leave for work, the gym, and other life things that happen. So, the printer has had time idling where it was not printing, turned on, or warmed up. It takes roughly 5 minutes for me to prep my printer each time I print something if everything goes smoothly. I also change out filament rolls when I get around 150 grams or less remaining, and sometimes the CR10 doesn't cooperate when I try to feed it new filament. I have done a pretty good job of placing PLA Orders in advance to when I will need more. Luckily, I haven't had to wait on filament more than once. I also spend time between prints preparing the next parts in Blender to fit to my printers build plate to save time. I do my best to sand the parts in one go so that by the time Bondo dries on the 1st part I filled in, I have finished filling in the last part in the same sitting. From there I start sanding. The sanding process up until now was all done by hand. No sanding block or mouse sander. But this year I was gifted a Mouse Sander. and oh boy has that been an absolutely massive help on time and effort. There are still portions I need to hand sand, and I will address this in my next update once I have completely sanded the chest. The glue I had used until now was E6000 Which is a great adhesive, but it does not set extremely fast. I will be using Superglue to set the parts together as it should dry a bit faster, and the parts will not slide apart. -

Ben Stoddard, 3D Printed ROTK Build Thread

Benjamin Stoddard replied to Benjamin Stoddard's topic in Rogue One Build Threads

Dark CMF Thank you very much. I'm aiming to achieve level 3 Centurion with this build. I do however believe that some of my parts may be a little off in specifics. I am doing my best to deal with them as I go, to make the number of changes I make an absolute minimum. The more detail the better, as extra eyes on a project always help, and if anyone down the line uses this thread to help them with a 3D Printed TK, the more detail the better. -

Ben Stoddard, 3D Printed ROTK Build Thread

Benjamin Stoddard replied to Benjamin Stoddard's topic in Rogue One Build Threads

Hovi Mic Tips have been attached with E600. The Frown still needs to be painted Gray. and I have a few parts I need to address on the helmet. Some of the helmet has some black speckles on it from when I taped off and sprayed the brow black. There was slight leaking and I plan to fix this by blocking the black off with painters' tape and spraying the helmet with white once more. I also have a few parts that I need to re-sand to make it smoother as in the right lighting, I can still see some layer lines. Prior to this, I need to add some Bondo to fill in the small gaps where I glued together the 3 sections of the helmet from printing. Pictured Below: As per the last picture, the CRL States: "Any gap between the ears and the helmet will only appear to be a seam, not any bigger." I am unsure if the current gap is too large, or if I will need to fill in the gap. and if so, must I fill this gap completely? Separate from the Helmet, I have printed the Butt-Plate, Cod Piece, Front and Back Belt, Thermal Detonator and the "O II" Details for the back plate. I mentioned earlier that I had a few rolls of small amounts of filament left over from larger prints, and I used those rolls for these pieces. A real Filament killer is how much support these parts need. To save filament I recommend either cutting your print to fit to your build plate in several pieces or orient your prints in a few directions to see what costs the least amount of filament. With that being said, it would also help you with cleaning your prints off afterwards if you make sure that any of the detailed parts do not have a lot of support around it. You can see my mistake in the 3rd picture below. First, I will say that I moved across the United States, and a few of my printed parts were damaged in the move. It's nothing that some superglue, Bondo, and paint can't fix though! I also ran into a slight issue with my printer once I unboxed it. I was in a new climate, and I do not have a heat shield to help retain the printer's temperature, so it loses a lot of heat in radiation. Secondly, as I was excited to start up my printer and get going on my TK, I did not ensure that the printer bed was leveled still! I have a few small scratches on my printed, but nothing that requires a new bed. Previously, I had been printing with just the bed and nothing on it to help with adhesion other than heat. Over time, my bed became dirty, and it needed cleaning. MAKE SURE YOUR PRINTBED IS CLEAN! I have sense put blue painters' tape on my printed to help with adhesion. I started up the 1st piece of the chest, and as it reached 90% completion, the PLA unstuck from the bed, and I had a big spaghetti mess of plastic when I checked after I ate my dinner. I restarted the print after leveling the bed. and again, around 90% it failed. But this time, I had a layer shift. You can see the layer shift at the very top of the chest piece. What happened was the adhesion to the build plate was not strong enough, and when the extruder moved back and forth, it pushed the print slightly to its side. From here, I used Elmers stick glue in combination with the blue painter's tape. I put a small bit under the tape, and an even layer on top of the tape to give the 1st layer something to really grab onto and stay. After this, the prints were coming out fine. In the last 2 weeks, I have printed the Main Chest, and Back plates. With support on still With Supports removed -

Ben Stoddard, 3D Printed ROTK Build Thread

Benjamin Stoddard replied to Benjamin Stoddard's topic in Rogue One Build Threads

After the wet sanding was complete, I hit it with several coats of white to ensure that none of the original color of filament would be seen through the base coat. At this point the arms have been hit to their extent for paint. I'm going to wait to rig everything together until I have completed the painting on the entire suit. The helmet traps, tears, and ears were sanded and painted separately in the similar way to the rest of the helmet. Attaching was done with E600 Glue. The helmet after black on the brow, gray in the tears and traps. Still need to attach the rear traps and paint the teeth gray. Additionally, I have to add the backing for the frown, vents on the cheeks. Wire that I used for the Hovi mic tips are actually mesh I cut out from cricket containers I ordered from Josh's Frogs. -

Ben Stoddard, 3D Printed ROTK Build Thread

Benjamin Stoddard replied to Benjamin Stoddard's topic in Rogue One Build Threads

After the entirety of the Helmet was printed, I began the process of sanding, sanding, sanding. I chose to keep all of the parts separate so I could manipulate the pieces and get into the crevasses easier. It took me several days to completely sand the helmet, and glue it together with E6000. Sanding the small greebles was very time consuming because of the fine details in the ear and getting in the teeth holes. I used Bondo Glazing and spot putty as well as Rustolium sand-able filler and primer in combination with grits of sandpaper going from 80 grit up to 400 grits. After finishing each piece, I assembled the main helmet. From here, I sprayed it with a new color to help me see any imperfections that I had missed previously. I then went over the entire helmet with 800 grit and a wet sand to ensure it was nice and smooth. At this point I had been working on the right arm aswell, doing the same sanding with Bondo and filler primer. -

Ben Stoddard, 3D Printed ROTK Build Thread

Benjamin Stoddard replied to Benjamin Stoddard's topic in Rogue One Build Threads

And there is the 1st chunk of the Helmet finishing up on the print bed. I had a partially used roll of PLA Filament from a previous print and it ran out with the last 3% to go, so I had to pause the print and load in a brand-new roll. After this, I made sure to keep track of how much each print would require prior to starting it up. -

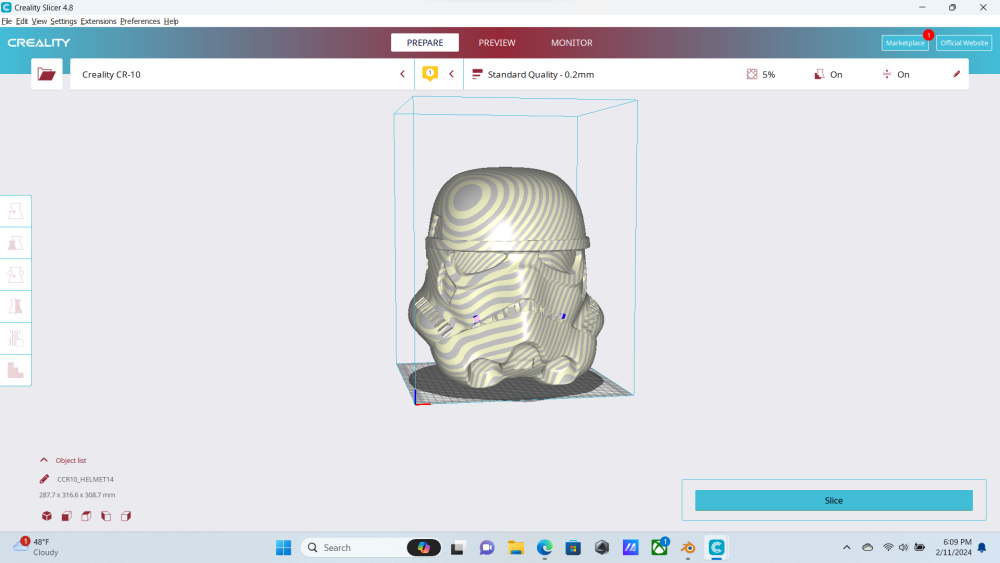

Hello Everyone, I have been looking to start my TK Build for quite some time. Slowly but surely, I have been printing out parts for a ROTK. I have recently moved to Virginia, and am extremely new to the forums, and a wee bit nervous after navigating my way around the "Getting Started" forums. Nevertheless, I am excited to get through my very first build and would be greatly appreciative of any constructive criticism, or helpful pointers for my build! Some Administrative Information: I am printing off of a Creality CR-10 V2, With a build volume of 300 x 300 x 400 mm. Majority of the project will be done with Zyltech PLA. 1.75mm diameter To scale the armor to myself, I am using "Armorsmith Designer" to the best of my ability. The files I am using are from Pewpewcrafts.com (any modifications to the actual armor I need to do will be post printing as I am not a blender wiz) Above is the preview of the 3D model from pewpewcrafts website. First piece I decided to print was the Helmet. for 2 reasons 1: The Helmet is going to need the most attention out of all pieces of the armor (in my opinion). As it has multiple greebles I needed to print separate to the bucket, it has the most "complex" paint job in comparison to the rest of the suit. 2: Its the coolest part! Therefore, I need to do it first, right? This being said, The Helmet after being scaled in Armorsmith Designed is ever so slightly too large for my printer. To work around this, I cut the file into 3 seperate parts. -The face, cut just behind the ear. -The back of the Helmet, which is the ear and behind. -The top of the helmet which I cut just under the brim of the "eyebrow".

.thumb.gif.3133dfe8baa328ad146bfe40afe330f0.gif)