-

Posts

4,043 -

Joined

-

Last visited

-

Days Won

23

Content Type

Profiles

Forums

Gallery

Articles

Media Demo

Everything posted by gazmosis

-

Really surprised you didn't just get a real folding stock

-

There is no set width. Use what is comfortable

-

If you are referring to the ones that appear next to your profile, you will receive the badge once you apply and your armor is approved.

-

If you think there is too much scuffing, clean them or touch them up. Just have a balance between your armor and boots.

-

trooper12's RT-Mod ABS ANH Stunt Build

gazmosis replied to trooper12's topic in Build Threads Requireing Maintenance

Get yourself a hobby iron if this bothering you. They are usually around $20 and are miracle workers. -

You drink no caffeine do you?

-

If it's anything the other Rubies stuff, I'd pass

-

Thanks guys

-

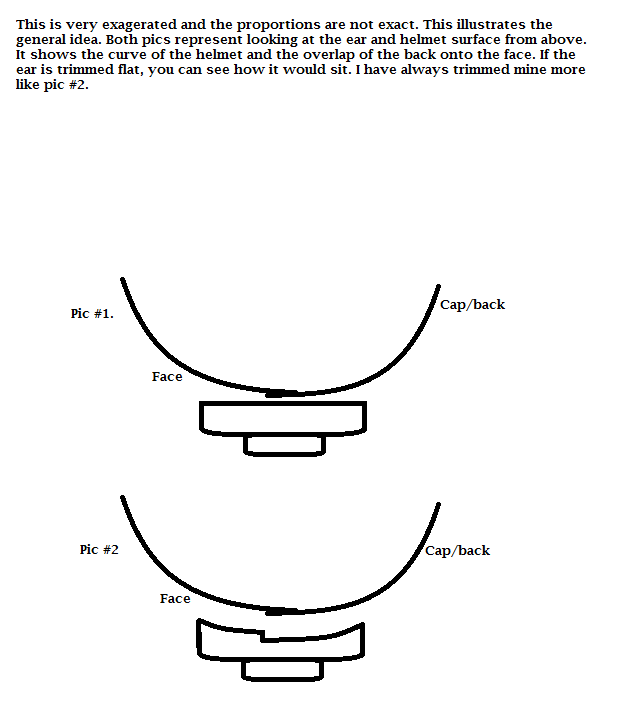

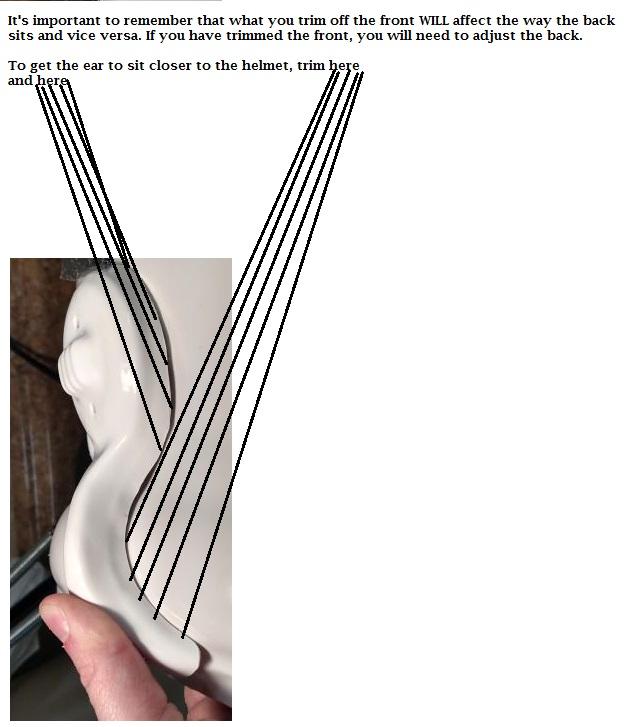

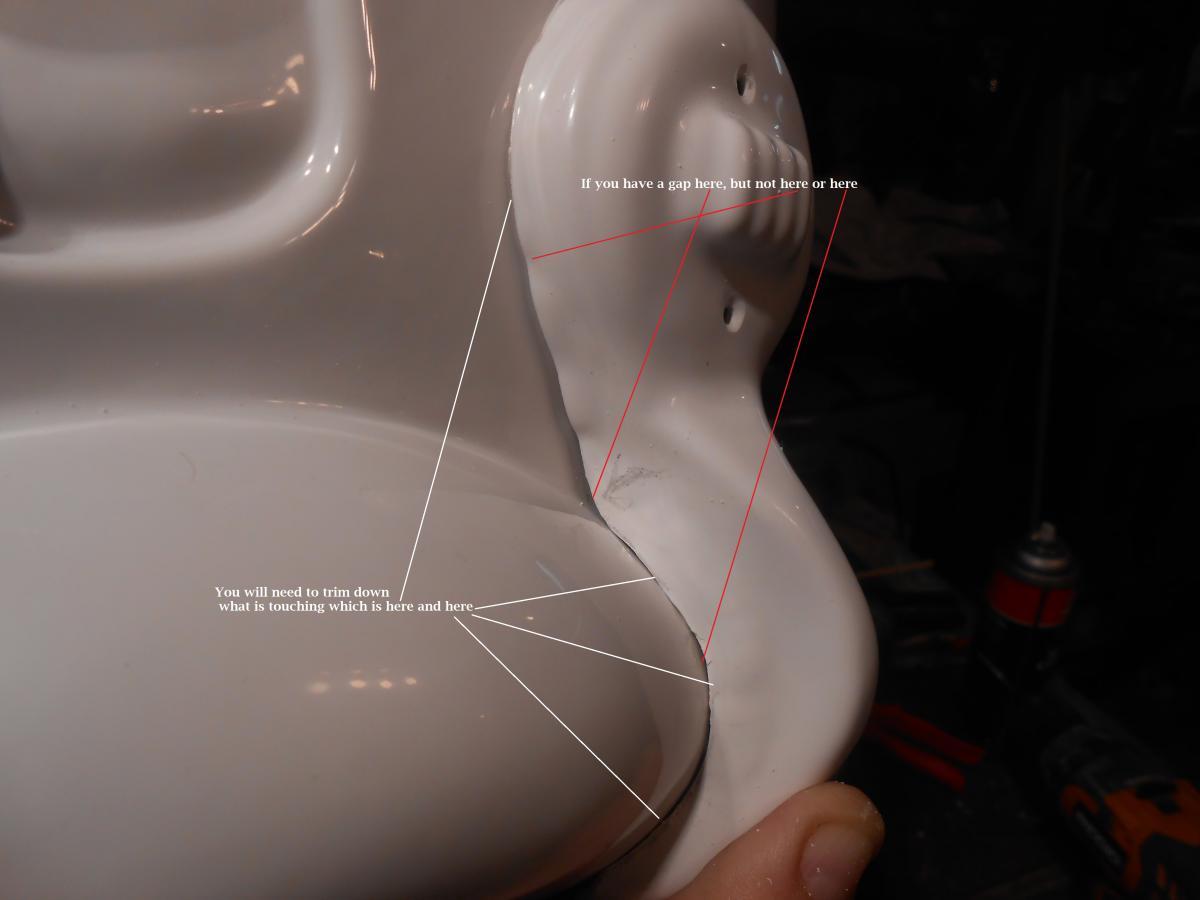

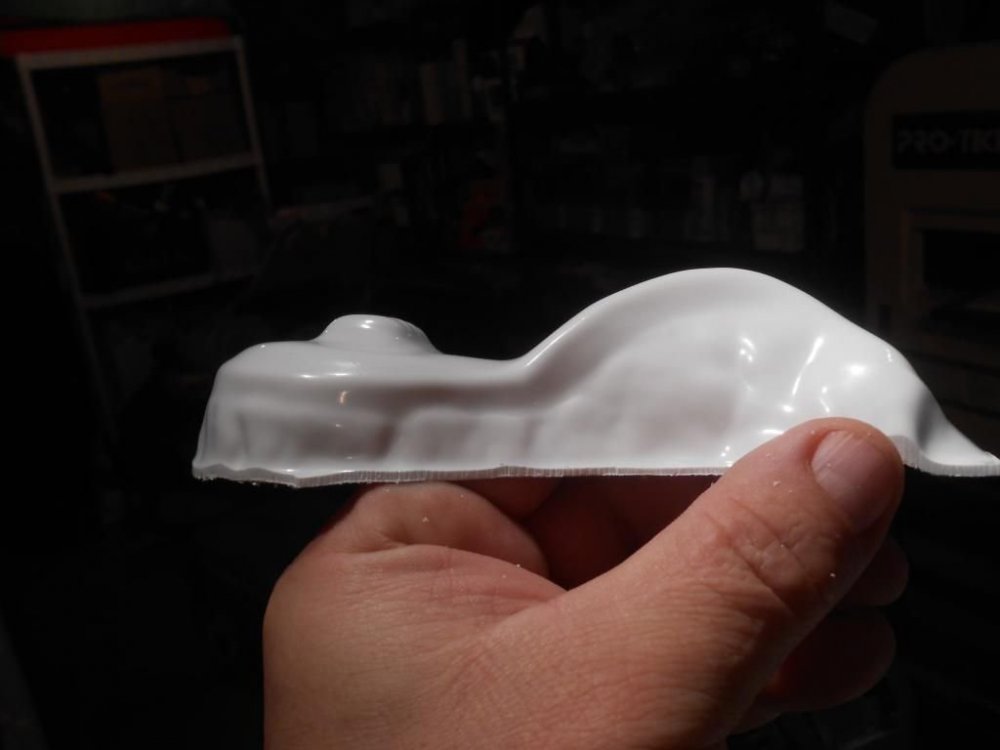

Hey there troopers!! Unless you have your armor maker build your helmet for you, every other armor build will have a helmet and every helmet will have ears to trim out. THE EARS!!!! GAHHHH!!!!! These words have struck fear deep in the butt plate of troopers all over the world. First and most important thing to remember is the the ears on the original helmets were FAR from perfect.For this reason alone, you really shouldn't be so hung up on making your ears sit so flush that there isn't even the slightest gap. However, there are some of you that are perfectionists and there is nothing wrong with that. In either case, whichever result you plan on achieving, having a basic understanding of your approach will help you to avoid making that embarrassing call to the armor maker asking for another set of ears.(Unless you were lucky enough to buy ATA that supplies two sets!! WAY TO GO Terrell!!!!) Keep in mind that there are both things to do and NOT to do. Your equipment can make this more of an art project than a worrisome task. These are my weapons: With a light, controlled touch, you can shave 1/2 millimeters at a time in a specific area or along a line edge. Along with removing the material is knowing what and how much material to remove. NEVER JUST EYEBALL IT!!! To properly monitor this, you will need one of these: Lastly, you will need patience. I know you want to see your lid done!!! After this, you are some paint and a few decals from struttin' your stuff!!! BREATHE!!!!! Let's get to it! will need patience. I know you want to see your lid done!!! After this, you are some paint and a few decals from struttin' your stuff!!! BREATHE!!!!! Let's get to it! The helmet has been riveted at the ears and along the cheeks so nothing moves. I have removed the vast majority of flashing from the portion that was on the vacuum table. I will first drill out the screw holes. Although the indents are there, shadows can play tricks on your eyes, so I mark them so no mistakes are made. I will slightly wiggle the bit to EVER SO SLIGHTLY increase the hole so the screw moves freely but is still well fit. Once the holes are drilled, it is time to countersink them so the screwhead sits flush. IMPORTANT!! Do not use anything but your hand for this step!!! NO DRILLS OR DRILL PRESSES!!! If the bit grabs the hole, it will go right through and there will be nothing you can do to stop it! Just spin it in your fingers and you will have precise control. You can see the difference in the two holes. As well as the difference in the way the screw rests within the holes. Note the shadow coming from the non-countersunk screw. Although there is still a slight shadow on top, this will all but disappear when the ear is tightened down. Now comes the fun! First thing to note is the original mold lines. These are ATA so the mold lines from the original helmet are here. Other armor makers may not have these. Consult the dozens of helmet reference pics we have here if that is the case. But if you have these lines, it is important to remember that these are from the helmet that these were off of....NOT YOUR HELMET!!!! The position you have your cap on your face to make the brow line higher or lower will affect the way the ears sit on the sides. For this reason, the ears must be trimmed to YOUR HELMET. The only kit I know of that the mold lines on the ears comes close to the final helmet without a huge degree of trimming is AP. As long as you use the dimples they suggest, the ears will sit correctly following the mold lines he provides. Anyway, back to these! It is important to note that your ears should look like seam covers and NOT 1978 headphones!! Note how thin the ears are on Han's helmet: You can see the mold lines on the back side very clear as well. I will start bu marking off a general line and trim that. I will smooth out the scissor edges and do a test fit to see where to start. I'm sure there are those of you that don't have the mold lines to start with and are wondering what to do. Note that the top of the ears always comes close to the brow trim and the horizontal ridge that runs around the back of the helmet. If you need to take a measurement between the brow and the cheek/tube crease and use that mark so you don;t trim too much off in that corner, do that. You can always trim more but you can't replace it if you think you trimmed too much. It doesn't need to be perfect, but there shouldn't be so much space that birds will want to nest in there!!! Here is the basic understanding of your approach: You will see this re-stated in the next pic but I can;t say it enough: What you trim away on the front can/will affect how the ear sits on the back. Don't work too long and remove too much without checking the other side from time to time.: Another thing to consider for those of you interested in a really clean fit, is that the helmet surface where the ears are is NOT FLAT! That's right!!! It's curved. Keep this in mind when trimming the round portion. This here is another area to consider if you want that super close fit. There are halves that overlap each other. If you want to, you can notch this out once you have decided the final resting spot for your ear. This is exaggerated, but it just shows what I mean. So here is my first fit. I know.....pretty horrible. It will get better. But first, and I believe this is where a lot of issues happen, I will determine my ear location: and mark it lightly with a pencil. This makes sure that my alignment and the trimming I do will all stay the same. If you ear moves around and you trim it willy nilly, things will be off.......I promise!! Now once you have a basic understanding of what will be affected if you trim certain areas, then you can proceed. TAKE YOUR TIME!!! Note what is touching and what is not. Trim what is touching the cheek to close any gaps that are not touching. My picture failed of the notch that I put in the top most portion of the ear so this one is from another build: Take note that this shows the right ear. I am working on the left so far. Anyway, You can see here, that the arrows point out what is touching and preventing the gaps from closing. Here are the spots on the back. Since you never want to eyeball a cut, I mark off what I will trim. After trimming that, you can see what is touching now (arrows) Noting what is touching, I mark what is to be cut. Now although the fit is tight around the cheek tube, I have a gap in the corner. The arrow points it out. In order to move the round portion closer to the surface, I need to take more out from around the cheek. There is a lot here so I can afford it. I will mark it anyway. After that trim, you can see I have a good general fit. Still needs a bit of honing, but a good fit. What have we NOT done?? The back! So let's go there for a bit. Without wordy describing, you can see the gaps, what is touching and my marks of what is touching so I know where to trim: Sometimes I like to even hit the INSIDE edge of the ear wall so that I am assured that the oter edge of the wall is the only thing touching the helmet surface. I do this with sandpaper so nothing gets out of control and too thin. So now we have a really nice fit in the back. Now is when I notice an issue after I got back to looking at the front. I traced out the original mold lines seen here: In my opinion, the ear is too thick around the curved portion. Using the same methods I used to get to this point, I reduced the curve by another few millimeters or so all the way around including the round portion. So after some additional tweaking and final sanding, the back side fits clean as does the front. I marked, drilled and installed the screws around the rank bar. I never pre-drill the lower location until the ear is fit. As you can see, I needed to drill it at an angle so the screw penetrated the face portion. When tightened, this drew the face up nicely to the curved section of the ear. and the result...(dramatic music please!) It's about as close as I am going to reasonably get it. Note how nice and flush the screws are in the recesses! The same will be done with the other side, but the same principles apply. I want to note that there have been other great ways to accomplish this either through a tracing wire or a toothpick attached to a pencil as a guide that rests on the helmet surface. This is just how I do it. To me, planning, staying constant, slow and steady yields good results. I hope this helps someone.

- 22 replies

-

- 13

-

-

People carry their weight different. You need to first decide which TK you are shooting for. Like Germain said, it is foolish to try to make an ANH/ESB suit look like ROTJ when ROTJ armor already exists and vice versa. Scott nailed it when it comes to AP requiring a thin framed person. A measurement around the fullest part of you ( your belly button) will determine if this will fit properly. AP really fits well up to roughly a 34 inch measurement. Beyond that you will either need shimming or move to a different armor that allows a 36 like TM, RS, ATA, MTK,

-

Kit Clarifications for my first build

gazmosis replied to Jedisaber's topic in Getting Started - Read this First!

Nice Tim! Specifically the EIB applications which require a picture of the strapping systems. -

Kit Clarifications for my first build

gazmosis replied to Jedisaber's topic in Getting Started - Read this First!

The only thing that even resembles anything you can buy that goes towards the strapping system is the webbing snap plates and the original metal bracket system that was used on the original suits. With either one, you will still need to fashion pretty much all your straps using either elastic, webbing , or both. There are few centurion requirements regarding strapping for the exception of visible hardware(side split rivets, male snap on the right side, crotch split rivet and crotch male snaps) the only strap that really shows is the one in the shoulder bells that goes around the bicep. This needs to be black and around 3/4 inch wide. The other important straps are the wider straps that connect the chest and back under the ribbed shoulder bridges. These need to be white and made from elastic or webbing. Elastic is more accurate. The straps that attach the shoulders to that white strap are black, and the straps that attach the drop boxes to the waist belt should be 3/4 white elastic. The rest of the interior strapping is really up to you how you want to do it. Just make sure everything except those chest to back shoulder straps are black. Did I miss anything?? -

storm trooper armor supply list

gazmosis replied to shamankid's topic in Getting Started - Read this First!

Unless you plan on becoming a distributor, the initial investment to make a proper set of ANH armor from scratch and not be guaranteed the right result, will FAR outweigh the cost of buying a set from one of the makers here. Give us your body type and measurement around your belly button so we can better guide you. -

TK 10251 Requesting ANH Stunt EIB Status [RS][420]

gazmosis replied to Artstar's topic in Request Expert Infantry Status

Alright Artie!! Welcome back and congrats on the approvals of your other costumes AWESOME photos at the end there!! *Note* Artie originally applied for EIB back in Dec of 2013. There were some issues that needed to be addressed as well as a slight re-organization of his application pictures. Thank you for working with me on this so we can finally move forward!!!! Now let's look at your armor!!!!! CRL and EIB Requirements: ​Darth Aloha's original assessment noting excessive side gaps has been resolved. You have successfully reduced yourself to eliminate that! Congrats!!!! There were several blasters pictured with some issues. A single blaster was chosen to represent with and an incredible one it is! You armor reflects all necessary elements for EIB. With that, I would like to congratulate and welcome you to EIB!!! Other-Armor Fit/Assembly: In this section, myself and your fellow troopers make suggestions toward improving the over all look/fit of your armor. Unless stated specifically, no suggestions here will affect any application. Twan mentioned this above and cannot agree with him more; your kidney and ab tops are very far out of alignment. I am not saying they have to make a perfect line across the top, but they need to be adjusted to align better than you have it pictured. This point will be brought up again in "Centurion Suggestions" below. I love your natural weathering!! Looks very authentic! It is not possible without replacing your belt to fix this next point. The rivet position on the outer most portion of the belt should be placed so the rivet cover sits just off the edge of the belt. I changed the right one on this pic so you can see the comparison of what I am talking about: I will say again how nice your blaster is. It can be nicer if you added a little weathering and silver details that are present on the real Sterlings specifically around the trigger group like this: Something else that Eric brought up in the original assessment was the location of your holster strap mounts on your belt. I agree they are too high. They should be within the lower half of the belt however, unless you replaced your belt which I am not going to make you do, this cannot be repaired unless someone has come up with a genius way to repair fabric so that it's undetectable. If you wanted to take your accuracy one step further, you could dab a little black on those thermal detonator screws. Centurion Suggestions: There are a couple things I'd like to see done before you apply for this badge. I will bring up the alignment of your ab and kidney tops. This needs to be remedied somehow. While we are on the subject of your sides, CONGRATS again on the reduction of YOU! Now, you have some unnecessary overlap on your left side that can be trimmed away to bring the rivets closer to their proper locations.I marked it in red: The male snap on your right side ab corner and your crotch rivet will need the paint removed. These were not painted. I went through basically every frame of the photo references to see if there was a screen trooper that had the tape like you have on the left side of your chest. I could not find one. If in fact these are repairs, you should strengthen these from the backside by whatever means you want: Poorman's fiberglass (t-shirt/superglue) extra plastic reinforcement or whatever. But those areas need to be cleaned up on the surface. If you do decide to move forward with a Centurion application, you will need a new back pic showing your armor with your holster attached. Congratulations again, Artie!!!! -

Going back to your two belts, use the bottom belt. You have three rivet points ( one in the middle and one on each end. ) however, the dimples in the outer most rivet points are far too close to the boxes. They should be closer to the edge of the belt with the final rivet cover sitting slightly off the edge.

-

That helmet is just an awesome sight. Nice tube stripes! They' eb been getting thin on other builds recently

-

trooper12's RT-Mod ABS ANH Stunt Build

gazmosis replied to trooper12's topic in Build Threads Requireing Maintenance

If you have access to a hobby heating iron, you can massage those notches out -

And I agree. I am going to lock this thread as it has come as far as it can and still be productive which it is quickly approaching NOT being. The information is here. The comparisons are made. The people will decide which they want to buy.

-

New airsoft MK4 L2A3 soon on market

gazmosis replied to skyone's topic in General Weapons Discussion

$500. That's painful -

Ridiculously minimal. I hope Roy is ready?!

-

Looking good there brother!

-

Forcesensitive RS props abs ESB build

gazmosis replied to Eddie TK Head's topic in Build Threads Requireing Maintenance

Yeah but he doesn't sell them -

TK-77177 Requesting ANH Stunt EIB status[SDS][419]

gazmosis replied to Shrapnel's topic in Request Expert Infantry Status

Hey Simon: Great follow-up! Sorry about the assumption of the thigh straps being attached to the inside of your ab. I see those snaps and they are only usually used for that purpose in that location. My bad. Anyway, With your correction of the calf closure, I put through your EIB badge. Congratulations and welcome to EIB!!! Regarding your upgrades, you never stated which adhesive you used in your assembly. If in fact is was something that you can get the halves apart with damage, the process of upgrading your seams ma seem daunting until you get done with the first one. After that, you will have the hang of it. If it is something that you just won't get to right now, I would at least, cut the overlap on your calf closure so the halves butt up to each other and install a cover strip of around 25 mm in width to your calves. This will at least get one upgrade chalked off the list. You can use Velcro or the metal hooks attached to elastic to keep them closed. We hope that you can make this happen! In the meantime, enjoy your EIB quality armor and get out there and make people smile!!!! -

Forcesensitive RS props abs ESB build

gazmosis replied to Eddie TK Head's topic in Build Threads Requireing Maintenance

Oh if only someone could find a crate load of those!