Leaderboard

Popular Content

Showing content with the highest reputation on 06/23/2023 in all areas

-

Filling in those areas will be a bit of work, Alex, but it's not nearly as hard as you think. What I suggest is to sand down the areas (shown by Mario) and using Bondo Glazing /Spot putty. This is miracle stuff. Unlike regular Bondo which requires mixing, it is a paste that you can simply apply with your fingers or a craft stick. It fills fine to medium lines like magic, dries hard in less than 20-30 minutes or less and is SUPER easy to sand! Just don't go too heavy. I build a lot of resin/3D items and would not do one without it. A couple of coats of paint after final sanding and you will be golden!2 points

-

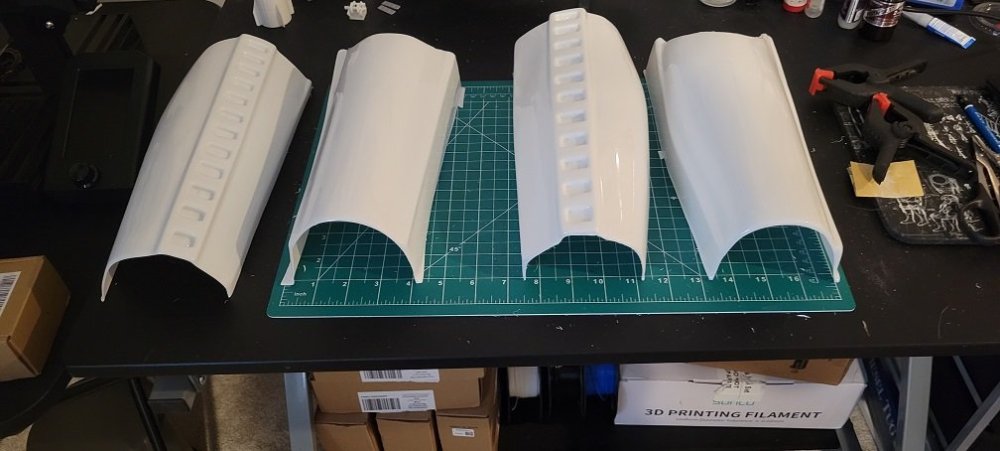

Copy that. No problem at all, sir. I'll get those taken and uploaded tomorrow evening or sometime on Saturday. However, I'll aim for tomorrow night.2 points

-

2 points

-

Legion Profile: https://www.501st.com/members/displaymember.php?userID=707&costumeID=126 Trooper Information Name: Justin Philpott FISD Forum Name: evnltr Legion ID: 9921 Garrison: Midwest Garrison Height: 5'9" Weight: 175lb Costume Information Armor Maker: RS Props (ABS) Helmet Maker: RS Props (ABS) Gloves and ESB Hand Guards: RS Props Neck Seal: ImperialSeamstress Soft Belt: RS Props Boots: Imperial Boots Holster: RS Props Electronics: Aker amp / Helmet Fan Kit Blaster: Blaster Factory Armor Photos Thank you for your consideration! Please let me know if you have any questions or need to see any additional details that I haven't provided.1 point

-

@gmrhodes13thanks, will definitely use that. Also, thank you for the return edge link. Just what I needed!1 point

-

Unfortunately some threads had out of date information as well as non recoverable images (photobucket fiasco) or link no longer works due to forum migrations, as such some have been archived. Updated list of info and how to threads here1 point

-

1 point

-

30. Webster/Rochester Library Summer Reading Kick-Off, 21 June 2023 We also had an AT-AT Driver and Emo Kylo Ren, but that picture hasn't been shared yet. Hopefully this works: Video from Garrison Excelsior's Facebook1 point

-

The first cut is always the hardest A great thread from @justjoseph63on return edges you may find handy Good luck with the rest of the build1 point

-

Hi Alex. I'm started working on you EIB app . Youe E11 blaster looks great but there are some details that we'll need you to make a fix . The CRL states for Level 2: 3-D printed blasters can not contain visible print lines, and must be sanded smooth for a more realistic appearance. There are some visible lines in your blaster that will need a little more sanding and a cape paint to give it a smooth finish. Thank you.1 point

-

Quick update after some minor blaster surgery. I mostly reassembled the E-11 so I could get a better understanding of where I can place the electronics. The muzzle cap had a large groove cut into it with a hacksaw and various Dremel bits to allow the installation of the muzzle flash device. I won't be using the kit barrel as it is really not needed. it can't be seen and leaves less room for electronics in the forward tube. I'm trying to place all the electronics in the main tube so I can keep the guts of the magazine in place I removed the installed fire selector switch in preparation for the BlastFX one. I found that the cocking action is very stiff and "grindy". You can actually feel and see little slivers of aluminum powder and shavings every time you weenie the action. This could be worked out over time, but I've never seen anyone cocking the action on an E-11 in the movies, so I don't need it here! Blaster is mostly reassembled. You can see that the selector switch is removed. I'll have to drill out the hole slightly to accept the post from the BlastFx version. I may also have to cut the post down slightly so the selector lever sits flush with the left side of grip body. And yes, I was listening the Gordon Lightfoot while grinding away. Something soothing about The Wreck of The Edmund Fitzgerald as you grind away at metal... I discovered a small issue with the end cap that I hadn't noticed before. The main tube has a grooved locking ring attached with 3 screws (visible in image) to the rear of the tube. This allows the end cap to lock into place. You basically line up little tabs on the inside of the cap with the grooves, push in slightly against the main spring, and turn clockwise. Once locked into place my end cap sits clockwise slightly, with the top being aligned at roughly 12:30 instead of 12:00. Locking ring on the Blasterfactory website. How my end cap sits vs how it should attach: On the real Sterlings there is a locking device (tab?) on the bottom just forward of the end cap. It has a spring and pivots when pressed which disengages a little tab that allows you to remove the end cap. Blasterfactory has included this little locking device with a spring, which is nice, but it is mounted about 1/4" forward of where it should be. It is also slightly off the bottom centerline of the main tube. Locking tab too far forward. The backend should overlap the end cap. There is a little stub on the inside of the locking tab that should sit in the small groove in the end cap. In the right image you can see the centerline of main tube in blue. My cap is locked in position with the center in green, and the black locking tab is off center in red. These "should" be easy fixes. Both the end cap locking ring and the black locking tab are held on with screws. I just have to re index everything and drill new holes. The muzzle cap surgery took a couple hours of cutting, grinding and filing down. I started with a couple simple hacksaw cuts with the muzzle held in a vice. I then used various Dremel bits to hack and grind away at the material. Thankfully this is aluminum and not steel! Unfortunately, the Dremel skipped a couple times and put some minor dings into the nice smooth paint job. These will be easy to sand out, but will necessitate a new paint job. Here it is basically done. I had to grind a small rounded bit out of the forward end of the slot to accommodate the led bulb of the flash unit. It's hard to capture in a picture, but I also had to grind a rounded groove at the bottom of the channel to accept the round circuit board of the flash unit. If I attempted to have the entire groove the depth needed for the flash unit, I may remove too much material and get close to the front sight cutout. Flash unit in the groove. The flash unit circuit board is a rounded "star" or "flower" shape, and one of the points / petals sits in the additional round groove at the bottom of the channel. In this pic, the muzzle piece is held upside down. So the muzzle sits just at the bottom (top in this pic) of the big hole. If I tried to center it I may remove too much material and get too close to the front sight groove. By me carrying out the surgery the muzzle flash board sits about 1/2 to 3/4" more forward. so it will be seen better. Back to the workbench!1 point

-

[53] 10.06.2023 -- Galactic Academy Event Hagen Arriving just in time for seeing everything up on Friday, we were already facing high temperatures. The whole area turned out to be huge with lots of hills and not much shadow. Still, we got everything ready and arrived the next day at 6am to start the event. The troop had been organized by the Galactic Academy Jedha Campus of Germany and was at an outside museum for old crafts. Several other clubs, as well as the local police and fire department had been invited as well. Us TK's started off the day with a patrol across the area, meeting a recruit, posing with the fire department and arresting Mandalorians and Rebels alike. Due to the heat a lot of the time was spent backstage at our booth, making sure to stay hydrated and cool. In the afternoon we started the parade, only to have to stop and re-start twice due to people collapsing from the heat and having to be driven to hospital. Once we were through with the parade it was time to cool down with the help of the local firemen and then suit-down. Over the course of the day the event managed to collect over 4000€ for a local children's hospice, which was an overwhelming success. At this point also a huge thank you to the organizers for the invitation, the lemon cake, and letting me stay at their place overnight! Oh, and for letting me try on a Jawa. I turned out to be an adorable Jawa. TK-66744 signing off picture by Pixelrabe1 point

-

Authentic gloves when it's cold. Authentic gloves when it's hot. Authentic gloves all the time.1 point

-

Not controversial at all for me, being a GML I usually know when someone has sold a costume, their membership profile is then updated, we also keep a record of what costume a member has worn at specific events and they are recorded in a yearly trooping database which makes things a lot easier at census time, obviously this is pretty easy to do in a smaller garrison of 45 than others which have 100's of members. I guess it really comes down to your command staff, how they set up local roles and rules and how proactive those people are in those roles and how the rules are followed.1 point

-

TIE reserve. That’s the reason. One of the most cost-effective ways to get into the Legion. But in reality I’m sure there are a myriad of reasons. Old guard TKs retiring, new TV shows bringing new fun kits in other detachments. Sent from my iPhone using Tapatalk1 point